1K Coating Technologies

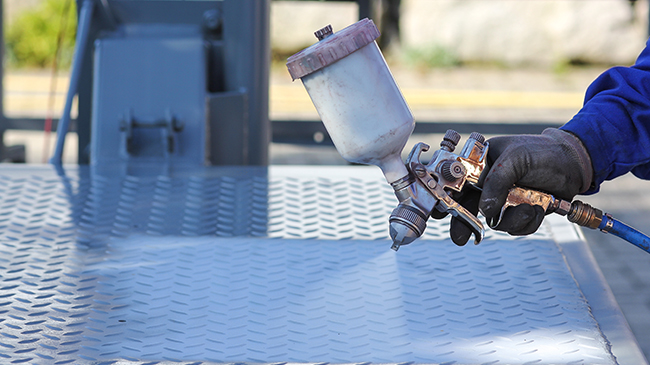

IPS SILOXZINC 1K

Inorganic 1K ambient curing siloxane-zinc primer for high performance anti-corrosion of ferrous metals.

- Single component ambient curing siloxane-zinc coating

- High zinc content (level 1, >85% Dry Film) content for enhanced corrosion protection.

- Fast drying and over coating times

- Used as anti-corrosion primer is high corrosion environments for steel infrastructure

IPS MIO 1K

Inorganic 1K ambient curing siloxane MIO anti-corrosion coating for steel substrates.

- Single component ambient curing siloxane mio coating

- High micaceous iron oxide content for enhanced barrier properties

- Fast drying and over coating times

- Used as primer or intermediate in coating systems as barrier coating for steel and concrete

IPS CERAMIC 1K

Inorganic ceramic 1K siloxane for high levels of abrasion resistance.

- Single component, ambient curing siloxane ceramic

- Fully ceramic coating for high levels of abrasion and chemical resistance

- High film hardness after curing

- Fast drying and over coating times

IPS 100

IPS 100 is a novel inorganic polysiloxane, single component, ambient TriCure chemistry, 100% solids and solvent free finish. Designed for fast shop throughput via fast curing, hardness development technology. VOC compliant coating that provides outstanding protection for weathering, splash zones of chemicals, anti-graffiti, non-yellowing and ultra UV degradation protection. Can be applied over anti-corrosion primers and intermediates to provide high performance coating system.

- Single component, ambient TriCure polysiloxane

- Operating temperature from -20 to 120℃

- Solvent free, 100% solids

- Ultra UV exposure protection

- Exceptional weathering resistance (ISO 11507)

- Hydrophobic (low dirt pick up) properties

- Available in range of gloss levels & RAL colours

IPS 100 CC 1K

1K solvent free siloxane clear coat for protection of steels and concrete provides graffiti resistance.

- Single component, ambient cure siloxane clear coat

- Ultra UV resistant finish coat for non-ferrous metal work

- Provides high gloss anti-graffiti resistant finish

- Solvent free, Low VOC coating

2K Coating Technologies

IPS PRIMER 2K

2K epoxy polyamide surface tolerant anti-corrosion coating for steel, galvanised, aluminium, stainless, concrete based substrates.

- Two component epoxy based anti-corrosion coating

- Surface tolerant primer for application over mechanically prepared steels

- Can be applied over etch or sweep blasted galvanised surfaces

- Good spraying and mixing properties.

IPS GLASSCOAT 2K

2K epoxy polyamide ceramically filled surface tolerant root coating for sub ground service of steel and galvanised substrates.

- Two component epoxy-ceramic root primer

- High abrasion resistant coating

- Suitable for steel and galvanised markets.

- Spray or roller applied up to 500 microns DFT per coat

- High Solids, Low VOC

IPS 220 2K

2K epoxy siloxane top coat with high levels of UV, chemical and abrasion resistance. For use over Performance Polymers anti-corrosion primers. Available in all RAL and BS colours.

- Two component epoxy-siloxane finish coat

- High solids, low VOC

- Very good weathering resistance (ISO 11507)

- Suitable for application over anti-corrosion primers and intermediates

- Tintable to RAL and BS colour standards

- Good hardness development and chemical resistance

- Anti-graffiti properties

IPS FLOORCOAT 2K

2K epoxy siloxane tintable floor coating with high levels of UV, chemical and abrasion resistance designed for concrete substrates. Available in all RAL and BS colours.

- Two component epoxy-siloxane finish coat

- High solids, low VOC, fast curing properties

- Applicable in coating films up to 250 microns DFT

- Tintable to RAL and BS colour standards

- Good hardness development and chemical resistance

- Anti-graffiti properties

- Interior and exterior floor applications